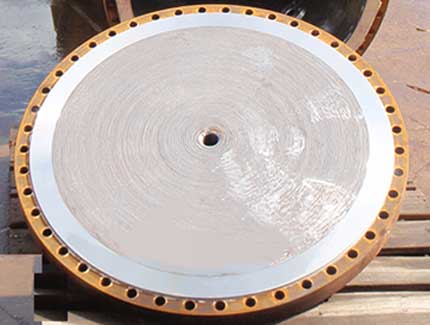

Cladded Equipments & Critical, Exotic Fabrications

Explosion cladding is a solid state welding process that uses precision explosions to bond two dissimilar metals while retaining the mechanical, electrical and corrosion properties of both. The process is most commonly used to clad steel with a thin layer of corrosion-resistant alloy metal, such as stainless steel, brass, nickel, silver, titanium, or zirconium. However, explosion welding can join a wide array of compatible and non-compatible metals; with more than 260 metal combinations possible.

The explosion weld is achieved in milliseconds; therefore, no bulk heating occurs, and the metals experience no dilution. NobelClad is the only company that can deliver high shear strength and high tensile strength across every type of combination we join.

In the world of oil and gas production and refining, corrosion-resistant alloys and explosion welded clad metals offer important economic and environmental benefits. They permit safe containment of oil, gas and related process fluids; ensuring a long useful life, which improves operating efficiencies. Overall, explosion welded clad materials can reduce equipment costs, enhance safety, and provide exceptional durability all while providing peace of mind.

Fossil fuel and nuclear power plants cooled with seawater can benefit from titanium-clad condensers and heat exchangers. Explosion welded clad offers a cost-effective solution for corrosion-resistant alloys required to handle low-quality cooling water. Our clad plates are used extensively for heat exchanger tube sheets, and the largest tube sheets are used in the final low-pressure condensers.

| BENEFITS | PRODUCTS |

|---|---|

| Cost Effective | |

| Lightweight Design | FLAT Plates |

| Composite Strength & Performance | Tube Sheets |

| Crevice Corrosion Resistance | Other custombuilt products |

| Temperature Uniformity |